Candle Wax Wood Counter Finish (with Stain And Beeswax Finished Supports)

Hiya folks!

So if you haven't read my previous WIP posts ( Making a Quarter Corner Floating Standing Desk from Reclaimed Wooden Cable Reel & DIY Reclaimed Wooden Cable Reel Semicircle Floating Table) this is just a follow up post about how they were finished!..

Once all the pieces had been fully sanded and I was confident that everything fit and was strong enough for (hopefully) a lifetime of use, I could get down to applying a wood finish before the final installation.

Final Finish for Table Tops.

For the cable reel table tops, I really wanted to maintain as much of the original raw reclaimed wood light colour. If I could I would have left them without any finish but I knew they would need to be protected.

After some research, the consensus seemed to be a polyurethane clear finish that is best applied via an expensive spray system and that I could only find 4 liter tins of locally!!

Nope, that wasn't going to do.... I had had some experience with making a paraffin wax finish for sculptures in the past which still looked great and hadn't yellowed at all ( unlike the yellowing that eventually happens with a beeswax finish) and with a little research I found that a paraffin wax finish was not unheard of for wood. Though probably not the best protection, it would do for what I needed the tables for.

All the info I found online about paraffin wax wood application was either using an already prepared bought wax finish or melting candle wax on wood with a heating mechanism like a blow torch though (which I didn't have).

I decided to use the recipe I usually made (just heated turp+white paraffin candle wax) as it would be easy to make and apply, plus would just cost pennies! (or rather a few ringgit).. :) With a little testing, I found that after the turpentine had completely evaporated the colour of the wood was very close to the original raw wood hue, with a smoother satin finish. I loved it!!..

|

| How they looked originally, mostly unsanded and newly sawn to the pieces needed for the tables. |

Materials:

- White Paraffin Candles

- Turpentine

- Double Boiler

- Portable Stove

- Brush (I used a 3" one)

- Old Clean Rag

- Gloves (best to use these when buffing with the rag as turpentine can absorb through skin).

- Face Mask (I didn't have one, but I made sure to do this outside in a very well ventilated area)

Preparing the Wax and Application.

|

| Melting the Paraffin candle wax about 50/50 with turpentine in a double boiler. |

The whole process was done outside to dissipate the turpentine fumes as much as possible during application.

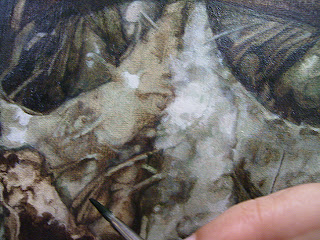

Once the wax had melted and was relatively hot I quickly brushed it on the wood in small segments (about a plank at a time) before buffing off the excess quickly with a rag. I didn't bother too much with extra wax left in the deep grooves at this point as this would be removed later with a small screwdriver and rag.

|

| Quickly buffing off the excess wax. |

After the wax had been applied to all table tops, I went over them once again with a cloth, buffing the surface and removing extra wax that had been caught in the grooves. I was careful not to buff too much as I wanted to maintain just a nice satin finish to the wood.

These were left to dry for a few days till the turpentine smell had dissipated before the final installation.

Table Brackets and Frames Final Finish

For the supporting pieces of wood I just so happened to have a leftover selection of finishes to choose from - a good tinted alkyd varnish, an IKEA Varda outdoor stain and an IKEA Behandla wax finish.

The varnish would have been great but after much deliberation and research I decided on staining all the supporting wood with the Varda then give them a beautiful sheen with the Behandla wax finish. It would be just so much easier to apply and I felt would give all the protection needed. The dark finish of the supports would contrast beautifully with the light table tops as well!

Staining alone would have resulted in a rather dry, matt, rougher look to the wood than I wanted. However applying the Behandla beeswax finish over the stain gave the perfect conditioned satin finish I was looking for and the whole proses was super easy.

|

| Behandla and Varda Wood Finishes |

|

| Applying the Behandla Wax finish with a brush. This was left on for 15 mins then the excess wiped off. |

|

| All pieces stained and waxed. The stain on the plywood base was left a lot longer before buffing off to get a darker stain that matched the other wood. |

|

| How it looked after the stain and wax finish had dried. |

With that done, all that was needed was patience as I waited for everything to dry fully (about 24 hours for the Behandla) and the turpentine smell of the table tops to disappear ( a few days) before installing the tables in my studio!..

You can check out the full WIP's of these tables at:

&

Thanks for dropping by!.. :)

I love wood, I always try to take care of its proper protection.

ReplyDeleteCompletely worth the extra effort for solid wood items!.. I concur :)

Delete